Environmental quality management

ENVIRONMENTAL IMPACT MANAGEMENT

Challenges, Risks, and Impacts

Thaioil Group conducts a comprehensive review of the environmental risks and impacts on an annual basis. In 2023, the Company recognized several challenges arising from environmental factors, such as the intensive actions of climate change, including the establishment of Carbon Neutrality and Net Zero targets, air quality management, such as control of Volatile Organic Compounds (VOCs) emissions, compliance with environmental regulations, circular economy, preparation for drought situations, and biodiversity conservation. In addition to these challenges, Thaioil Group recognizes the impact of the business operations on local communities, which requires proper management to mitigate the risks. Consequently, Thaioil Group has elevated the management approach in construction projects and has implemented control over the production process to prevent adverse effects on the community's lifestyle and well-being. To achieve this, the Company has adopted the sustainability or Environment, Social, and Governance (ESG) management process to enhance work process and procedures that can reduce environmental impacts on communities and other stakeholders. This approach will be applied to all sizes of Thaioil Group's construction projects. Likewise, the Company maintains strict control over the current production process to ensure normal operating conditions. Moreover, Thaioil Group places significant emphasis on inspecting regulatory compliance and preparing for emergencies that may arise and impact the environment.

Commitments and Targets

Thaioil Group strives to enhance the Company’s environmental management system in alignment with global trends, aiming to drive towards sustainable business growth while maintaining environmental awareness. According to the Environment, Social, and Governance (ESG) practices, the Company aims to reduce environmental impacts and create long-term business opportunities in collaboration with the community as specified in the policy. In addition, the Company has adopted an environmental management system in accordance with national and international standards to oversee and continually improve the management system and environmental master plan. In 2023, Thaioil Group elevated the policy commitment in “Thaioil and Subsidiaries’ Quality, Security, Safety, Occupational Health, Environment, and Energy Management Policy” through the approval of the Board of Directors to consistently drive the most efficient environmental management practices.

Targets

| Indicator | Unit | 2023 Target | 2030 Long-term Target |

| Complaints on environmental incidents | Case | 0 | 0 |

| Non-compliance with relevant environmental laws and regulations | Case | 0 | 0 |

| Major non-compliance with ISO 14001: 2015 standard | Case | 0 | 0 |

| Significant oil and chemical spills into the environment | Case of significant spill | 0 | 0 |

| Compliance with excellent environmental governance standards in petroleum and petrochemical refineries | Percentage | 100 | 100 |

Management Approach and Performance

Environmental Management

Roles and Responsibilities

Thaioil has defined the roles and responsibilities for implementing Quality, Security, Safety, Health, Environment, Energy Management (Thaioil QSHE policy), with the goal of efficient resource management and continuous improvement. The responsibilities extend to executives and employees at all level, including

- (1) Chief Executive Officer and President

- • Appoint Manager of Quality System to be a representative for QSHE Management Representative (QSHE-MR) according to the organizational structure and responsible for:

- o Develop, utilize and maintain management system and document.

- o Encourage all relevant personnel to be aware of the needs and expectations of all stakeholders. This includes understanding and complying with all legal and other requirements related to the QSHE management system.

- o Report the performance of QSHE management system to management team for review and recommendation for improvement.

(2) All management levels and Department managers

- • Clearly identify the roles and responsibilities of those involved in QSHE management system to ensure that processes meet objectives and targets and respond to needs and expectations of all stakeholders.

- • Sufficiently allocate resources, such as human capital, skills, facilities and technology, to prepare and maintain the management system.

- • Provide clear directions and communicate to employees and contractors at all levels to understand and strictly adhere to the QSHE policy.

- • Employees and contractors at all levels comprehend and strictly comply with the QSHE policy in order to efficiently achieve the goals and objectives.

Management Approach

Thaioil Group takes responsibility in the three key areas, namely Environment, Social, and Governance (ESG) while the principle of the circular economy is adopted to drive the business forward. The environmental strategies and master plan in the short, medium, and long term have been established to grow the business while being environmentally conscious and minimize the environmental impacts throughout the production chain.

- • Long-term Strategy: Thaioil Group is committed to promoting business growth while maintaining environmental consciousness and creating long-term business opportunities. This commitment comprises two key strategies, namely the Net Zero GHG Emissions strategy and the Circular Economy strategy, both of which are supported by a well-defined governance structure.

- • Short- to Medium-term Strategy: Thaioil Group is committed to minimizing environmental impacts at their sources and promoting ESG practices that are resilient to changes and aligned with global trends and the long-term business strategy. The Company has aligned the strategic management plan towards O2Bx (Operation Excellence to Business Excellence). In addition, the “Refinery in The City” model has been adopted in the management approach in pursuit of business excellence, focusing on three main areas on environmental management, social management, and governance compliance. To efficiently achieve these business excellences, Thaioil Group has implemented a management approach known as the “CARE Concept”, which is outlined as follows:

- • C – Control Right: Controlling environmental impacts and maintaining compliance with the regulatory requirement. The environmental management has been elevated through Permit to Work-Job Safety Environmental Analysis (JSEA) to prevent and minimize potential impacts on communities that may be affected by the Company’s production, construction, and transportation activities. The Company has also proactively prepared to mitigate impacts from the Clean Fuel Project (CFP), which is in the process of commissioning and start-up. This aims to maintain the trust of the surrounding community through active community engagement.

- • A – Awareness & Communication Right: Raising awareness, engaging in communication with stakeholders, and building trust in Thaioil Group’s ability to prevent and mitigate the impacts of business operations. This is outlined in the Company’s Sustainability Management Policy and Corporate Social Responsibility Policy. This aims to enhance the quality of life for communities and society, contributing to sustainable growth.

- • R – Recycling Right: Managing natural resources efficiency through the 3Rs strategy (Reduce, Reuse, Recycle) and the circular economy principle, in order to support the Sustainable Development Goals.

- • E – Eco-Society Right: Creating value to society through the "Partner for Life CSR" concept to instill volunteerism and corporate social responsibility among employees. Also, the Company promotes a "Volunteer Culture" and encourages employees to design initiatives for communities towards "Share Value with Society".

Thaioil Group operates business with transparency and fairness, prioritizing the appropriate return of benefits to all groups of stakeholders as well as emphasizing environmental protection and community well-being. To achieve this goal, the Company implements a comprehensive environmental management plan that considers both internal and external environmental factors (Environmental Outlook) to align with the needs and expectations of the stakeholders. This involves communities, government agencies, executives, and employees who have expertise in environmental topics, as well as environmental regulations, laws, and global megatrends, etc. All factors are analyzed to identify business opportunities and enhance a five-year environmental plan referred to as the “Environmental Master Plan”. This plan is used as the key framework to drive sustainability in environmental management and ensure effective environmental management to achieve the environmental targets.

Thaioil Group enhances employees’ knowledge on environmental management in alignment with the sustainability and environmental policies and practices. For instance, the Company organized training sessions on carbon taxes, Net Zero GHG Emissions, Carbon Footprint Organization and Carbon Footprint Products. In addition, statutory training was also conducted for environmental managers and practitioners in pollution treatment systems, which was attended by 34 attendants. The Company is committed to providing training on an annual basis to enhance employees’ knowledge of environmental management for continuous efficiency.

Furthermore, Thaioil Group governs and develops environmental management systems according to accepted standards at the national and international levels. For example, ISO 14001 (the standard on environmental management excellence), ISO 26000 (the standard on corporate social responsibility) under the CSR-DIW project, PTT Group’s Operational Excellence Management System (OEMS), the best practices in biodiversity management, the Global Reporting Initiative (GRI), and the best practices identified from the Dow Jones Sustainability Indices (DJSI) assessment. To improve and develop environmental management systems, these standards are adopted in risk assessments, environmental prevention and mitigation measures, operational controls, monitoring, inspection, and reporting processes, as well as the execution of the proactive and reactive environmental indicators. The Company has also improved and developed the environmental management system throughout the production process to end products across the value chain, covering operations in various conditions as follows:

Production in Normal Operating Conditions

Thaioil Group conducts risk assessments on environmental issues and implements preventive measures to mitigate environmental impacts at the sources on an annual basis or when significant changes occur. Moreover, the Company has been steadily enhancing production efficiency in accordance with the Environmental Master Plan which serves as the operational framework comprised the following topics:

-

• Governance Structure• Technical Procedures• Climate Strategy• Water Resource Management• Eco-efficiency• Biodiversity• Supplier and Contractor Program• Environmental Audit• Management Information Solutions

For the refinery unit expansion project, Thaioil Group applies the environmental standard specification, which encompasses the requirements, laws, best practices, and fair stakeholder perspectives, based on the environmental principles. This aims to establish the operating framework for the Green Construction Project. The framework remains continuously responsive to the requirements and expectations of relevant stakeholders.

Highlighted Projects

In 2023, Thaioil Group implemented additional projects as follows:

• The Company has upgraded the control of Volatile Organic Compounds (VOCs) from the best practice developed with the industrial factory group, a member of the Petroleum Institute of Thailand and the Center of Excellence in Hazardous Substance Management, Chulalongkorn University. This upgrade enables the Company to control VOCs emissions in the maintenance process, storage tanks, and flare. In addition, the Company closely monitors air quality, especially VOCs emissions. In 2023, Thaioil Group developed the Scrubber Unit Machine to reduce the VOCs emissions, and subsequently, the machine has been efficiently utilized in the maintenance of oil storage tanks. Moreover, all relevant functions have monitored the efficiency of flare capacity and adjusted maintenance procedure to reduce VOCs emissions. This project will help the Company to prepare for the refinery turnaround in 2024 and 2025.

- Scrubber Unit Machine, developed to reduce VOCs emissions during oil storage tank maintenance in 2023

Production in Abnormal Operating Conditions

Abnormal operating conditions

Thaioil Group has established the Environment and Community Relation Committee (ECRC). The Company works in partnership with the government agencies, academic institutions, and communities surrounding the production area to enhance environmental management and mitigate impacts on all stakeholders through thinking, working, correcting, learning, and developing together. This collaboration starts with setting proactive guidelines and jointly addressing issues together to resolve the issues during abnormal operating conditions. Environmental performance is continuously monitored and assessed 24 hours a day, seven days a week by the operational team. The ECRC also organizes activities and communication platforms to track and monitor environmental performance in compliance with the requirements, regulations, and operating targets. To minimize environmental impacts on surrounding communities, the ECRC organizes monthly meetings to address concerns and suggestions for further improvement. Additionally, the perception survey is conducted with the community on an annual basis.

Meeting for the preparation of monitoring and recovery plan with government agencies

Environmental Emergency Conditions

In 2023, the prevention of oil and chemical spills is a crucial concern for Thaioil Group’s business operations. According to the criteria of the Oil Industry Environmental Safety Group Association (IESG), Thaioil Group experienced one case of significant oil and chemical spill, which was promptly managed. The Company has implemented management approaches in four aspects to efficiently manage the oil and chemical spill as follows:

1. Prevention

-

1.1 Using the ships that have passed the safety standard assessment of the PTT Group Ship Vetting System. In this assessment, Captains of the Company and the PTT Group will assess safety documents, namely Ship Inspection Report Program (SIRE), an international standard of the Oil Companies International Marine Forum (OCIMF), ship information from international websites, such as Sea Website and terminal feedback of the ships shared with the PTT Group. These documents are reviewed and considered together with the ship quality audit assessment within the PTT Group to ensure the quality of the ships and crew members of Thaioil Group in line with international safety standards.1.2 Maintaining ports, buoys, and other equipment used for transferring crude oil and petroleum products.

For instance, the Company regularly maintains oil pipelines at the port and offshore buoys, safety joints, and ship ropes. In 2023, Thaioil Group’s Engineering Department conducted an annual inspection of the Single Buoy Mooring (SBM) in both the SBM-1 and SBM-2. In addition, the Company inspected the Conventional Buoy Mooring (CBM) and its chains. As a result, both the SBM and CBM system complied with the safety standards of the engineers.

.jpg)

.jpg)

-

1.3 Conducting tanker safety checks for both domestic and international tankers operated at Thaioil Group’s port. The Port Manager regularly assigns the practitioner to inspect tanker safety. In case of detected defects, the practitioner will inform the tanker’s captain and manager to resolve and prevent recurrence of such defects.

The tanker may be temporarily suspended under circumstances that the defects do not align with specified safety standards.1.4 Nominating employees in the port division to attend activities with IESG on a regular basis to exchange marine safety knowledge and ensure that operations align with international standards.

.jpg)

.jpg)

1.5 Organized an annual meeting between Oil Industry Environmental Safety Group (IESG) and the executives from Thai ship companies. As a member of IESG, Thaioil Group communicates information about ship and port safety, such as updated port rules or defects identified by random ship inspection. This aims to ensure that the Company has properly implemented corrective actions to improve safety condition in business operations, and prevent accidents and pollutions from both ships and ports.

.jpg)

.jpg)

2. Mitigation

Despite having stringent preventive measures that align with international standards, Thaioil Group has also developed the mitigation measures to cope with unforeseen incidents, for example, the oil spill incident at SBM-2 in September 2023, as below:

-

2.1 The Loading Master, who serves as the head of oil transportation operations for the Company, is required to notify the Emergency Shut Down (ESD) and close all valves on the ship to suspend the flow and pressure oil transfer system. Otherwise, it may lead to increased oil leakage to the sea.2.2 The service boat, that is stationed at the buoy, is required to close all valves of both floating and underwater buoy. This action prevents the flowing back of oil from the refinery's tanks into the sea. This action aligns with emergency procedures.2.3 The Loading Master, who serves as the head of oil transportation operations for the Company, instructs the contractors to deploy oil absorbent booms along the oil pipeline to control the oil spills. This action aims to control oil spill within a limited area and prevent it from flowing to the sea, otherwise, it becomes difficult to control.

The oil absorbent booms, prepared for use in the event of an emergency situation, are stored on the Company’s contracted vessels.2.4 The Company implements the oil spill prevention and response plan to prevent and eliminate water pollution. This aims to reduce and mitigate the environmental impacts until the situation is ultimately under control.

3. Prevention of Reoccurring Incidents

To build confidence for the government sector, the public, and all relevant stakeholders, Thaioil Group will investigate to determine the root causes of the oil spill. After obtaining permission from the government agency, the investigation will be conducted internally to explore the possibility of the incident and its causes. Simultaneously, the Company will develop a plan and take preventive measures to avoid the recurrences of such incident in the future.

.jpg) |

.jpg) .jpg) |

| Electrical test | Pressure test |

4. Personnel Development

Thaioil Group prioritizes personnel development to ensure knowledge and capability in oil and petrochemical spill management. In 2023, the Company conducted activities to develop and enhance knowledge of the personnel on oil spill cleaning. The activities in 2023 are described as follows:

- 4.1 Thaioil Group conducted the exercise of marine oil spill response as a Table Top Exercise to the on-duty operators assigned in the Company’s Emergency Plan. The exercise stimulated a scenario that the floating hose was broken at the SBM-2, resulting in an oil spill spreading to the Bang Lamung beach where it is the local fishery area and significant tourist destination that contributes to the local economy.

.png)

- 4.2 Thaioil Group assigned employees who had not completed the training to join Oil Spill Response (OSR) IMO Level 1 for Responder, operated by Oil Spill Combat Team (OSCT-Thailand) between September 13-15, 2023.

.png)

.png)

- 4.3 Thaioil Group collaborated with IESG in Sriracha area to conduct a Shoreline Assessment at Koh Sichang beaches. This aims to understand conditions of the island, which are vulnerable to the environment and economy. The assessment is conducted every five years to update the database to the most current information.

In 2024, Thaioil Group has developed the key plans as follows:

-

1. Participating with Oil Industry Environmental Safety Group Association in Sriracha area (IESG-SASC) to conduct the exercise on oil spill cleaning. This is a joint exercise with Thai Oil Public Company Limited, PTT Public Company Limited, and Esso (Thailand) Public Company Limited, which will be hosted by Thai Oil Public Company Limited.2. Conducting the 2nd Shore Line Assessment with IESG-SASC after the previous 5-year assessment. The purpose is to determine the significant changes of shorelines. In addition, the result of this assessment will be used to examine and develop the pre-incident plan in the case that oil reaches the shorelines.3. Organizing a workshop to enrich the knowledge and understanding on the response to a marine oil spill or chemical spill in first line level for personnel in the port division.4. Providing training on incident management of the marine paraxylene spill for the employees in Sriracha Oil Terminal of PTT Oil and Retail Business Public Company Limited.5. Developing personnel skills, expertise, and knowledge through nominating personnel for participating in trainings or conferences related to marine oil spill prevention and treatment

Highlighted Projects

In 2023, Thaioil Group launched development projects and upgraded the management approach in the abnormal operating conditions and the environmental emergency situations as follows:

- • Thaioil Group collaborated with the innovation department of PTT Public Company Limited to conduct the study and experiment of the Electronic Nose (E-nose) system. The system assists in monitoring, detecting, and notifying the unpleasant odors that arise from the production process and other activities and may affect the employees, contractors, communities, and other stakeholders. The system is active 24 hours a day, allowing the Company to identify the sources of unpleasant odors and make improvements promptly.

Experimental installation of the E-nose system in the Thaioil Group area

2023 Performances

.png)

Air Quality Management

Management Approach

Thaioil Group is committed to minimizing environmental impact to facilitate continuous business, while maintaining environmental consciousness alongside surrounding communities. To achieve this, the Company has established targets for controlling air quality, including Nitrogen Oxides (NOx), Sulphur Oxides (SOx), Volatile Organic Compounds (VOCs), and Particulate Matter (PM). Starting from the design phase, the Company selects and installs high-efficiency technologies that meet international standards to control its production processes. The Company also monitors and measures air quality at its sources and in the surrounding areas on a regular basis in accordance with a predetermined schedule. The Company also uses an air quality monitoring system that displays real-time results and tracks the performance of air quality against international best practices. The Company’s environmental management system and performance is audited and certified by an external party on an annual basis.

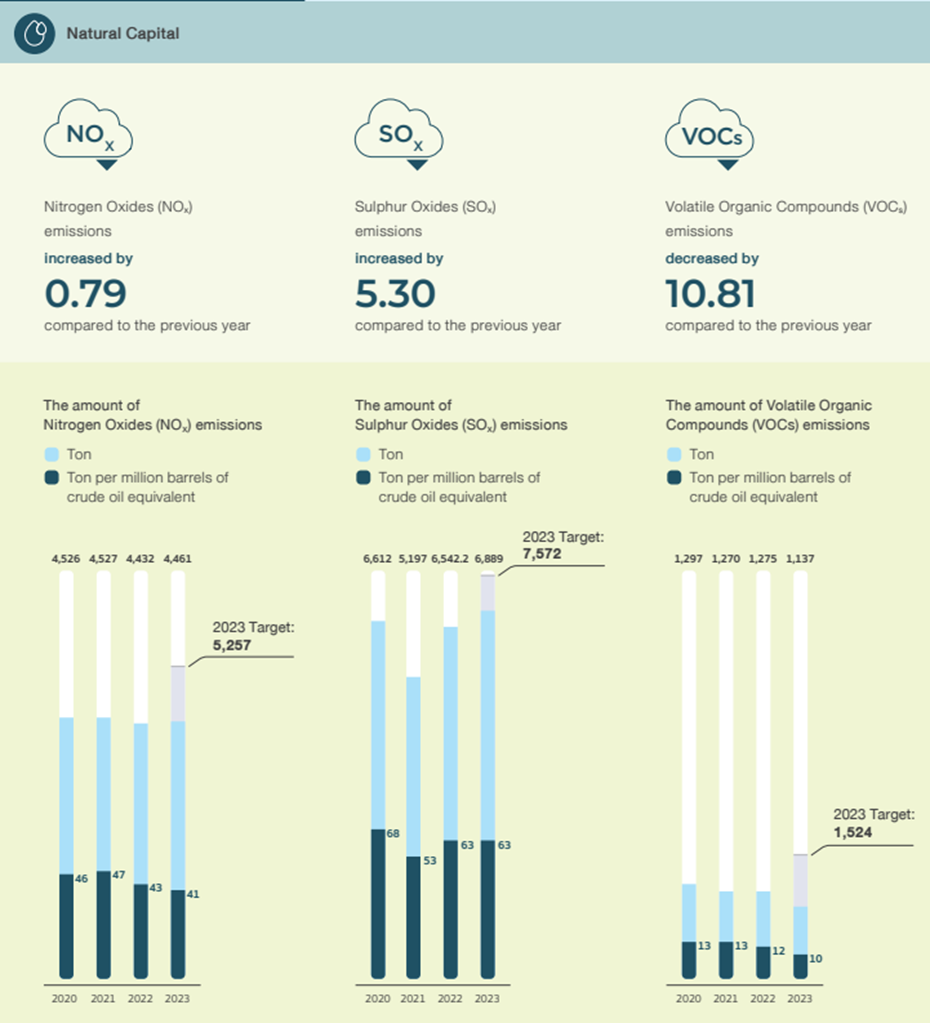

NOx and SOx Emissions Management

Thaioil Group assesses environmental impacts and determines preventive measures to control NOx and SOx emissions from the production process. The primary source of emissions is from fuel combustion. To control and minimize these emissions, the Company has installed high-quality technology that is internationally recognized and continuously operated the Sulphur Recovery Unit (SRU) system. The SRU system can effectively convert Sulphur from waste gases into a liquid product for use in other industries instead of emitting it into the environment. Furthermore, the Company upgraded all burners to Ultra-Low NOx in 2010 to effectively reduce Nitrogen Oxides emissions from combustion. The Company also controls the usage of low-polluting fuel over the high-polluting fuel and regularly monitors the smoke from combustion (White Smoke Monitoring) to avoid the impact on the community. Moreover, Thaioil Group measures the air quality both at the sources and in the surrounding communities by using advanced technologies such as the Continuous Emission Monitoring System (CEMS) and the Air Quality Management System (AQMS), respectively. The air quality is also measured and audited by an external party and reported daily in the Environmental Daily Dashboard. Consequently, Thaioil Group managed Nitrogen and Sulfur Oxides emissions at levels that were better than the required standard while achieving the set target in 2023.

In 2023, Thaioil Group implemented additional projects to control SOx and NOx emissions as follows:

- • Thaioil Group has conducted a feasibility study on Predictive Emission Monitoring System (PEMS) to replace the Continuous Emission Monitoring System (CEMS). This method is certified by USEPA and the information will be provided to the Department of Industrial Works for consideration as an alternative approach for monitoring air quality emitted from stacks, contributing to sustainable development in alignment with international standards.

VOCs Emissions Management

Thaioil Group manages Volatile Organic Compounds (VOCs) emissions through environmental impact assessment.

The Company implements preventive and monitoring measures of VOCs emissions from various sources within the production process, including flares, combustion, tanks, loading, effluent treatment plants, and fugitives, through operational excellence management as follows:

-

• Flares and Fuel Combustion: The Company monitors the efficiency of flare, maintenance process, and controls undesirable incidents that may emit VOCs emissions from the combustion tower.• Tanks and Loading processes: The Company selects the most suitable tank for storing chemicals and oil.

The Vapor Recovery Unit (VRU), installed with up to 99% efficiency, treats VOCs emissions from continuous product transfer.• Effluent Treatment Plants (ETP): The Company regularly tracks and monitors VOCs emissions to improve its wastewater treatment system. The ETP Cover Project has been initiated and is now in the process of installing an ETP Cover system to reduce VOCs emissions into the environment.• Fugitives: The Company controls and monitors ventilations through the VOCs emission leak detection camera.

The camera helps identify leak points in accordance with the regulations, international laws, and standards specified in the US Environmental Protection Agency (US EPA) since 2012. This provides opportunities for further improvement to prevent fugitive emissions.• VOCs Reduction Measures in Maintenance: The Company has amended the maintenance work procedures to align with best practices and ensure VOCs emission control below legal requirements in all activities.

In 2023, Thaioil Group implemented additional projects to control Volatile Organic Compounds (VOCs) emissions as follows:

- • Thaioil Group invented the “Scrubber Unit Machine” by adopting the Wet & Dry Scrubber Technologies. During the maintenance process, this machine assists in reducing the VOCs emissions to below 500 ppm before opening oil storage tanks. Currently, the machine has been successfully implemented in the maintenance process, yielding effective results.

Particulate Matter (PM) Management

“PM2.5 Taskforce” consistently monitors and determines the management approach to drive and communicate activities to control PM2.5 under the 4C measures (Control, Contain, Clean, and Check). These approaches have been implemented to reduce environmental impact at the sources, such as office buildings, production processes, construction projects, and community areas, as well as supporting governmental activities and measures. Besides, the Company regularly measures PM10 and PM2.5 by using the Air Quality Management System (AQMS) and undergoes audits by external parties. Likewise, the Company regularly communicates the PM2.5 management through ENVI E-newsletter to all employees.

Communication of PM2.5 Management through the ENVI E-newsletter

In 2023, Thaioil Group implemented additional projects under the 4C measures as follows:

-

• C-1 Control: The Company maintained the air quality at a better level than standards and legal requirements. Several activities were undertaken to limit the use of vehicle and road usage, including the promotion of carpool campaign, the change of carpool vehicles to electrical vehicle, and the adoption of “Fast & Flow” strategy to manage traffic flow. The Company also monitored and controlled the vehicles’ conditions and their black smoke, as well as ensuring the proper use of covering of dusty material on dump trucks.• C-2 Contain: The Company organized an activity to control the level of dust on walkways, aiming to reduce diffused and accumulated dust. The activities included installing a dust collection net, using tarp covers to prevent dust from transport vehicles, setting up wheel washes in the construction area, installing water spray, and providing dust protection masks for employees and contractors working in risk areas.• C-3 Clean: The Company established cleaning initiatives in buildings, lorry loading areas, and construction sites. These initiatives included activities such as carpet cleaning, air conditioner cleaning, 5S activities, Big Cleaning Day, and the TOP Green Road. In addition, the Company supported government initiatives to control dust levels on Sukhumvit Road by spraying water.• C-4 Check: According to the site audit measures, the Company tracked dust pollution levels from the Pollution Control Department station, including the TOP AQMS lorry station, and used a PM2.5 NONG PIM detector to assess air quality both indoors and outdoors.

2023 Performances

Environmental Expenditure

| Type of Expense | Unit | 2020 | 2021 | 2022 | 2023 |

| Capital Investments | Million baht | 57.4 | 425 | 13.14 | 108.86 |

| Operating Expenses | Million baht | 92.96 | 75.85 | 85.79 | 134.12 |

| Total Expenses | Million baht | 150.36 | 500.85 | 98.93 | 242.98 |

| Savings, cost avoidance, income, tax incentives, etc. | Million baht | 112 | 65 | 74 | 215 |

| % of operations covered (Revenue) | % | 100 | 100 | 100 | 100 |