Business

Thai Oil Public Company Limited

|

|||||||||||||||||||

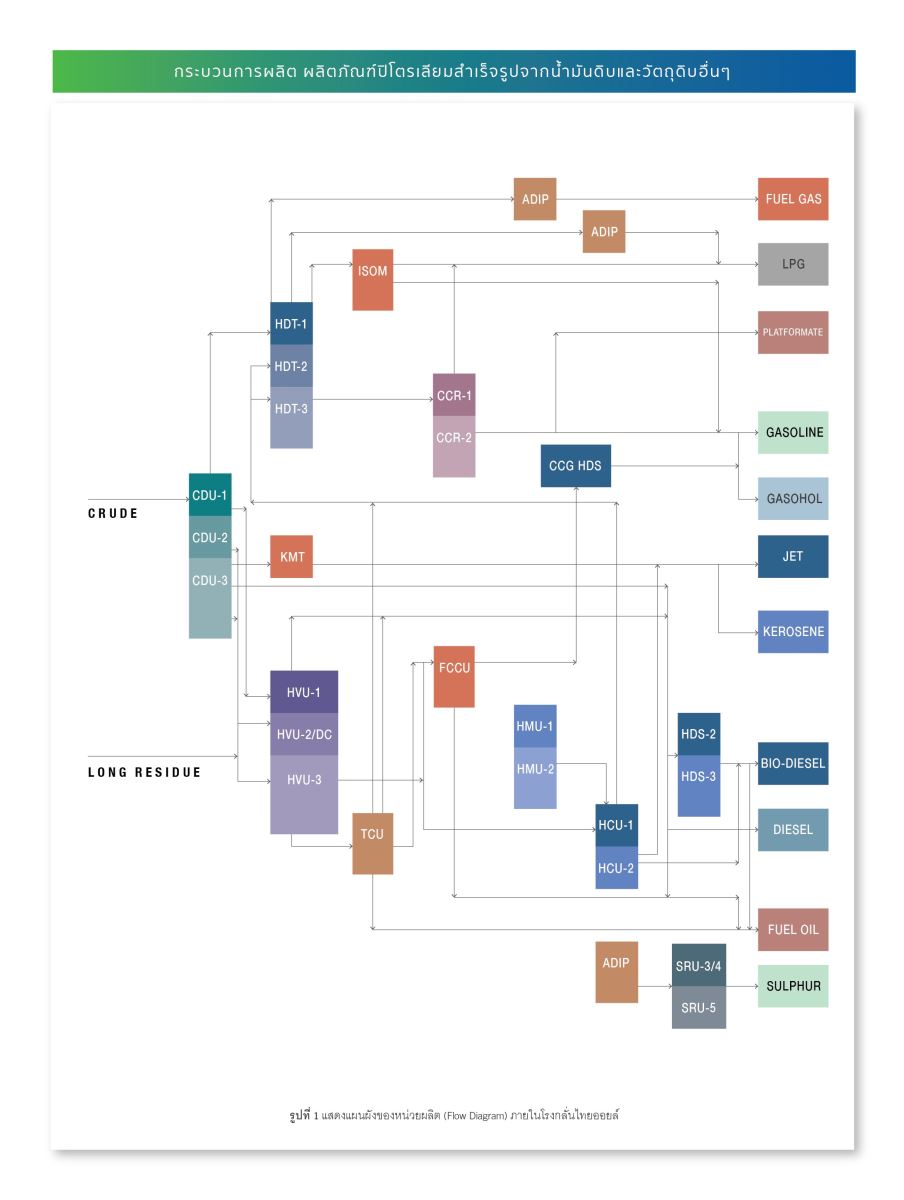

| Today, Thaioil refinery has a petroleum refining capacity of approximately 12,000 million liters per year or about 21% of the nation’s overall refining capacity and capable of meeting the domestic demand for petroleum at 35%. Thaioil refinery has been designed to create maximum value from the production system. As a complex refinery, the refining process involves various steps that take place in the crude distillation units, the upgrading units, and the quality improvement units, that make Thaioil becomes one of Asia-Pacific’s leading producers of high quality petroleum products. It also allows for flexibility in using raw materials or crude oil from various sources, and in adjusting the production level of each type of petroleum product to be in line with domestic demand. |

|||||||||||||||||||

There are 3 main units in Thailoil Refinery: |

|||||||||||||||||||

| 1. Crude Distillation Units | |||||||||||||||||||

| Responsible for distilling different types of petroleum through separation at different temperatures | |||||||||||||||||||

| 2. Upgrading Units | |||||||||||||||||||

| Responsible for upgrading lower value products to higher value products by means of chemical reactions | |||||||||||||||||||

| 3. Quality Improvement Units | |||||||||||||||||||

| Responsible for improving the quality of the oil to meet the required standards, as well as the removal of contaminants | |||||||||||||||||||

Process of Petroleum Production from Crude Oil and Other Raw Materials

|

|||||||||||||||||||

|

The Company’s refinery is located near Laem Chabang Port in Sriracha, Chonburi, which provides convenience in transportation whether by sea, train, truck, or through Thai Petroleum Pipeline’s multi-product pipeline. The company can, therefore, deliver its products to customers efficiently and at a reasonable cost. Through the years, Thaioil has been improving its refining technologies to ensure that they meet international standards. To reflect our determination toward continuous improvement and to create product and service reliability among our customers, the ISO 9001: 9002 and ISO/IEC 17025 was brought in as a tool to be used in production management and petroleum product testing laboratories accreditation respectively. Both systems have been successfully accredited by the Management System Certification Institute (Thailand) since 1996. Thaioil was presented with the TQC Award in 2009 for its management excellence. The company is determined to continue improving its management administration to meet customers’ demand and to create maximum benefits to all stakeholders in the supply chain. |