Human & Organization Development

Human & Organization Development

Challenges, Risks,

Over the past year, Thaioil Group has encountered several challenges, ranging from economic competitiveness, evolving environmental, social and sustainability polices, as well as rapid digital and technological transformation. In addition, the Company remains committed to its 3Vs business strategy, which emphasizes both domestic and international business expansion. These challenges have driven the Company to strengthens its organizational structure, human resources management, enhance employee capabilities, and adapt to evolving work styles. These efforts aim to equip employees with the right mindset, behaviors, and capabilities to effectively address with challenges and drive current and future businesses to secure sustainable and stable business growth.

Furthermore, Thaioil Group recognizes the diversity among its employees, including gender, age, and work locations. The Company has formulated a human resource and organizational development strategy with action plans that embrace diversity to respond to the needs of its employees in an inclusive and equitable manner.

Thaioil Group prioritizes the preparation and development of its workforce to drive the business towards achieving the organization’s long-term goals under the concept of “Toward Our Great Future With People Value”. Therefore, the Company has established a comprehensive Human Resources and Organizational Development Strategy as part of its 5 Years Business Plan, covering the following three dimensions:

- People Capacity

Thaioil Group focuses on workforce planning aligned with its 3Vs business strategy, while expediting the recruitment of employees to meet defined staffing targets. Additionally, the Company has developed an organizational structure, policies, and human resource management systems that align with its strategies for paving the way toward becoming a sustainable organization. - People Capability

Thaioil Group places great importance on developing its workforce to possess the knowledge and capabilities necessary to execute business strategies by accelerating efforts to equip employees with expertise and experience in new business development abroad, together with employee development in different areas such as innovation and leadership capacity building for future leaders. These initiatives are designed to support the organization’s sustainable growth. Also, the Company has incorporated Artificial Intelligence (AI) technology to enhance the efficiency and effectiveness of employee development processes. - People Way of Work

Thaioil Group prioritizes the continuous well-being of its employees by integrating the principles of Diversity, Equity, and Inclusion (DEI) into its work practices. This approach ensures fairness and fosters seamless collaboration within the organization. Additionally, the Company is dedicated to enhancing employee engagement and creating a balance between work and personal life. These efforts aim to improve the quality of life and forster lasting happiness for employees.

Targets

Workforce Planning:

Workforce productivity level in comparison with industry peers

2024 Target

1st Quartile

Quartile

2030 Long-term Target

1st Quartile

Quartile

Human Capital Development:

Readiness of core competency

2024 Target

94

Percent

2030 Long-term Target

94

Percent

Creating a positive employee experience:

Employee engagement

2024 Target

94

Percent

2030 Long-term Target

95

Percent

Human Capital Index (HCI)

2024 Target

85

Score

2030 Long-term Target

90

Score

Management Approach

and Performance

People Capacity

Thaioil Group prioritizes strategic workforce planning in alignment with the business strategies and directions to maintain a competitive workforce compared to industry peers. The Company also emphasizes proactive recruitment and hiring through the “TOP Talent Recruitment” strategy, which enhances workforce planning in three areas as follows:

- TOP Employer Brand

Define the Employer Value Proposition (EVP) and communicate it to target candidates to enhance awareness of the organization’s image and attract talents to join Thaioil Group. - Optimizing Process

Improve recruitment processes by integrating advanced technology systems to streamline and accelerate recruitment and selection processes, along with exploring new approaches to reach and engage with the target candidate group thoroughly. - Partnership Management

Seek strategic partnerships and establish efficient collaboration frameworks to further enhance the effectiveness of the recruitment and selection process.

- TOP Employer Brand

Strategic Workforce Planning and Talent Acquisition Performance in 2024 | ||

|---|---|---|

Human Capital | • Ability to recruit employees in desired positions 101% • Workforce productivity level in the 1st Quartile in comparison with industry peers • New hires 176 new employees • Percentage of open positions filled by internal candidates (Internal Hires) 97.67% | |

Social and Relationship Capital | • Provided scholarship to 105 students from 32 academic institutions • Provided internship opportunities to 118 students from 32 academic institutions • Shared knowledge and career advice to students at 70 academic institutions | |

People Capability

Thaioil Group prioritizes continuous human capital development to foster a skilled workforce capable of navigating the rapidly evolving business landscape and driving the organization’s 3Vs business strategy. To promote further skill development, the Company provides self-learning opportunities for employees through Thaioil Academy, the digital learning platform that enables employees to access training at anytime and anywhere. Employees can select courses and topics related to their work or personal interests, thereby cultivating a broad range of skills and competencies necessary for driving the business forward. Moreover, the platform encourages employees to share their expertise and engage in collaborative knowledge exchange.

Additionally, the Company aims to enhance employee competencies and capabilities to ensure readiness to drive corporate goals. The development programs emphasize knowledge exchange and practical experience, guided by the 70-20-10 learning and development principle. This initiative equips employees with in-depth knowledge and understanding, preparing them for work and fostering excellent performance that drives value creation and sustainable benefits to the Company.

Employee Development Programs for 2024

Course | Development Approach | Description of program objective/business benefits | Quantitative impact of business benefits | Percentage of FTE(1) participating in the program | |

|---|---|---|---|---|---|

1. Core Competency 1.1 Digitalization | Training, knowledge exchange with the experts, and practical experiences | Developing employees’ knowledge and expertise in digital capabilities by providing learning opportunities in areas such as Data Analytics, Data Science, Cybersecurity, and various digital tools including Power BI, AI, UX/UI, and SAP iRPA, etc. These initiatives also foster Digital Behavior among employees by encouraging them to utilize technology relevant efficiently and securely to their work. Moreover, employees can improve work standards, create innovative outcomes, and enhance overall productivity by integrating digital concepts into daily operations. | 374 | 9.63 | |

2. Expert Development Enhancement | Knowledge exchange with experts and hands-on practical experience through projects and assigned on-site work | Strengthening and cultivating profound expertise in core knowledge areas for employees through diverse development programs, such as HDS Catalyst Workshop, EDS Reliability Improvement Project, Process Capability Study, and Furnace Modelling Project etc. These courses aim to empower employees to apply the acquired knowledge with their work experiences and create value-added outcome for the Company. These initiatives contribute to domestic and international business growth, and play a crucial role in preserving vital organizational knowledge, ensuring long-term competitiveness. | 386 | 3.76 | |

3. Business Explorer Development for Growth | Training, learning through business simulations, knowledge exchange with experts, combined with practical hands-on experience through projects | Equipping employees with knowledge, skills, and abilities to enhance the business’s competitiveness and seek business opportunities that align with Thaioil Group’s three core business strategies. This is achieved through practical hands-on experiences in four projects that supports new business opportunities. This initiative allows the Company to create added value for the business and propel the organization toward sustainable growth. | 371 | 2.91 | |

Note:

1. FTE, or Full-Time Equivalent, represents the number of hours worked by a full-time employee per person per year.

Thaioil Group strives to develop leadership potential, which is essential to drive the organization and working team. The Company focuses on leaders’ readiness to handle the forthcoming changes and manage the team efficiently under uncertain and rapidly changing situations.

Leadership Development Programs for 2024

Course | Objective | Target Audience | Quantitative impact of business benefits |

|---|---|---|---|

Management Outing Workshop (Inclusive Leadership) | Developing leadership skills through the principles and behaviours of Inclusive Leadership. This approach focuses on fostering a deeper understanding of others, enhancing listening skills, and building trust. Furthermore, the program includes training on becoming Invisible Leaders – leaders who effectively engage with their teams and lead their teams with understanding. These leaders act as enablers, supporting their teams to strengthen engagement and boost productivity. | Vice President and above | 297 |

Engagement and Change Management Workshop | Developing integrated skills in change management and employee engagement by revisiting these skills through knowledge exchange with experts and the analysis of real-life case studies. Additionally, the program also includes practical exercises to enable Section Managers to apply these skills effectively in managing employees. The goal is to equip them with the ability to manage change appropriately while fostering understanding, happiness, and strong engagement between employees and the Company. | Section Manager | 186 |

As a result of continuous employee development in 2023, each full-time equivalent (FTE) received an average of 361hours of development and training, representing a total investment of 369 million THB. This investment is in response to business expansion and preparation for future challenges.

Thaioil Group recognizes the importance of career development and has developed career development plans for subject matter experts, technical experts (Technical Centre of Excellence), and sandbox explorers. These initiatives are designed to equip employees with the knowledge, capabilities, and experiences necessary for their professional growth along their career paths.

Moreover, Thaioil Group is committed to enhancing its competitive capabilities and fostering business growth by transforming into a learning organization. The Company has developed a Learning Organization Roadmap to promote continuous learning among employees. In addition, the Company encourages its employees to leverage their knowledge to create innovations that add value to the business through the “5 Dimensions of a Learning Organization” principle as follows:

5 Areas of Becoming a Learning Organization | ||||

|---|---|---|---|---|

Goal & Strategy | Organization Transformation | Strategic Knowledge Management | People Dynamic Learning | Learning Ecosystem |

A clearly defined goal and strategy to transform into a learning organization (LO) that is aligned with business strategies. | Implementation of policies, organizational structure, roles, and processes to support learning. | Implementation of effective systems and knowledge management processes. | A fostering of a learning culture in alignment with the goal of becoming a learning organization. | Designed learning technologies and platforms that facilitate and contribute to building a learning organization. |

Key Activities | ||||

Develop a strategic plan for a Learning Organization (LO) and create an LO roadmap to systematically outline the operational phases for building a learning organization. | Establish the TOP LO Policy and appoint representatives for each department as LO Inspirers and Knowledge Owners. | Focus on critical knowledge capture and sharing, as well as providing opportunities for employees to develop E-Learning content through KM E-Learning Creation Award initiative. | Encourage employees to embrace LEAD behaviors and organize initiatives to drive learning organization, such as Corporate Lunch & Learn and the LO Learning Challenge, etc. | Develop and promote a Learning Ecosystem by integrating various learning platforms into a cohesive system. |

Human Resource Development Operations Performance in 2024 | ||

|---|---|---|

Knowledge Capital | • Learning organization assessment resulted at 86% (Level 5: Optimized(1)).The assessment was developed upon domestic and international best practices with the external consultants. • A total of 63 ideas were generated through the Innovation Culture Promotion project, and the practical ideas have generated the potential benefit of approximately 108 million THB per year •188 Online Courses created by employees’ knowledge and expertise | |

Human Capital | • The Human Capital Index (HCI) of the Company was at 85 • 343 of knowledge that has been generated from Knowledge Management (KM). The Company’s benefits that have gained from leveraging knowledge for further development were amounting to 617 million THB • 94 % of employee readiness based on employee competency assessment. • The average annual employee development hours per person equal 361 hours per FTE(2) • Average employee development cost of 369,865 THB per FTE(2) | |

Note:

1. An Optimized Level indicates that the Company has integrated learning as the core of the business strategy and organizational culture. At this level, the organization has successfully implemented all dimensions of learning with exceptional proficiency.

2. FTE, or Full-Time Equivalent, represents the number of hours worked by a full-time employee per person per year

People Way of Work

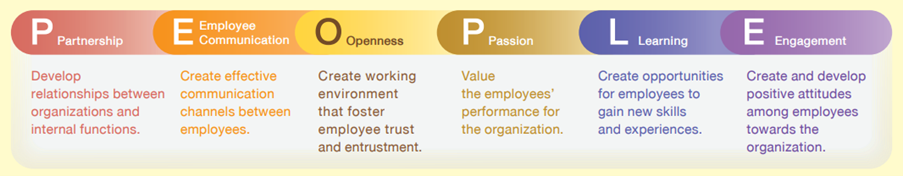

Thaioil Group prioritizes the quality of life and well-being of all employees, recognizing that they are pivotal to drive the Company’s businesses. To this end, the Company implements a range of programs and activities at both the organizational and departmental levels throughout the year. These initiatives aim to foster employee happiness and engagement under the framework of the PEOPLE Model, which responds to the diverse needs and expectations of employees across various dimensions. This approach ultimately seeks to cultivate lasting happiness and well-being among Thaioil Group’s employees.

The Company conducts an annual employee engagement survey and provides opportunities for employees to voice their opinions and suggestions through various activities, including management-employee activities, corporate recreational activities, and peer-peer engagement activities. Feedback gathered from these activities is then analysed to continually enhance the employee experience.

Furthermore, Thaioil Group promotes open communication for mutual understanding across all organizational levels, including executives, management, and employees, as well as open communication between team leaders and their members. In addition, the Company enhances supervisors’ understanding of the performance management system and career development system. This ensures that communication is conducted across the organization remains accurate, transparent, and in alignment with the Company’s unified standards.

Enhancing Employee Experience Operations Performance in 2024

Indicators | Units | 2021 | 2022 | 2023 | 2024 | Target 2024 | |

|---|---|---|---|---|---|---|---|

Human Capital | Employee received performance appraisal | Percent | 100 | 100 | 100 | 100 | 100 |

Employee engagement score | Percent | 94 | 89 | 92 | 98 | 94 | |

Employee satisfaction score | Percent | 94 | 95 | 94 | 98 | 96 | |

Employee voluntary turnover rate | Percent | 1.17 | 2.81 | 2.01 | 1.17 | 3.5 |

Key Highlighted Project

The Company recognizes that its workforce is a crucial driving force behind the successful execution of its core strategies. Therefore, prioritizing employee care remains a top priority for the Company. In 2024, the Company continues to pursue a “Happy Employee, Happy Company” environment through the SMILEX project, an initiative that builds upon the SMILE project introduced in the previous year. The SMILEX project focuses on six dimensions aimed to respond diverse employee needs, create a happy workplace environment, and prepare employees and organizational systems for sustainable growth and development. These efforts reflect Thaioil Group’s belief that employee well-being is essential to enhancing productivity and ensuring the organization’s long-term sustainable success.