Supply chain management

SUSTAINABLE SUPPLY CHAIN MANAGEMENT

Challenges, Risks, and Impacts

Thaioil Group procurement has placed an emphasis on sustainable supply chain management as the Company has several procurements with domestic and international partners, the potential opportunities and impacts on Environment, Social, and Governance or “ESG” must be considered as the key factors for business operations and continuity. At the same time, the Company strives to enhance the quality of life and generate sustainable returns for all stakeholders. To ensure the effective risk management in procurement process, therefore, the Company has assigned the procurement function to analyze and assess risks in various areas for all products and services on a regular basis, such as supply risks and sustainability risks. This approach enables the Company to identify the potential risks and challenges that may arise. As a result, the major challenges from the Company’s supply chain are outlined below:

- • There is a limited number of non-substitutable suppliers in the function that has high supply risks. This results in an insufficient number of suppliers during the bidding process. Consequently, the Company must invest more time in sourcing new suppliers. To handle this challenge, the Company has explored alternative approaches to formulate efficient procurement strategy. Meanwhile, the procurement functions need to collaborate with the other relevant functions, such as the end-user’s function, to develop preventive measures that do not affect the Company’s operations.

- • There are suppliers with high sustainability risks which can pose negative impacts on the Company, therefore resolving these sustainability risks before allowing those suppliers into the procurement processes is necessary. However, in the case that the Company discovers the sustainability risks during the operations, the Company will investigate the issue with the suppliers. If the supplier has the sustainability risk, the Company will issue a clear corrective action plan with a specific timeframe for the supplier to take corrective actions immediately.

Furthermore, the Company has established a grievance mechanism for suppliers to raise concerns and complain during the procurement process. To ensure transparency and ethical business practices, this mechanism has been posted on Thaioil Group’s website and governed under the internal audit process.

Commitments and Targets

Thaioil Group is committed to implementing sustainable procurement practices in line with Thaioil Group’s Sustainability Management Framework. This framework takes into account sustainable business, including Economic, Environmental, Social, and Governance aspects, together with the procurement principles of Clear, Fair, and Professional. This aims to integrate the procurement process to contribute towards achieving business strategies in accordance with international standards of ISO 20400: Sustainable Procurement. This will minimize the chance of business disruption and the delays caused by unforeseen events. At the same time, it will optimize the resource efficiency management to gain competitive advantage, create long-term mutual benefits for Thaioil Group and its suppliers, and maintain trust for all stakeholders. Therefore, the Company has determined key performance indicators (KPIs) in line with the Company’s performance as follows:

Targets

| Indicators | Units | 2023 Targets | Long-term Targets | |

| SCOC Acknowledgement | Strategic suppliers or significant suppliers acknowledged the SCOC | % | 100 | 100 |

| Key suppliers acknowledged the SCOC | % | 82.5 | 90 | |

| New registered suppliers acknowledged the SCOC | % | 100 | 100 | |

| ESG Risk Assessment | Number of proven complaints received from procurement process in the significant procurement projects, which have been verified and supervised by the internal audit process to ensure ethical and transparent business conduct. | case | 0 | 0 |

| Strategic or significant suppliers received a comprehensive ESG risk assessment | % | 85 | 100 | |

| Supplier Engagement and Satisfaction | Supplier satisfaction towards Thaioil Group | % | More than 90 | 95 |

Management Approach and Performance

1. Management Approach for Non-hydrocarbon Suppliers

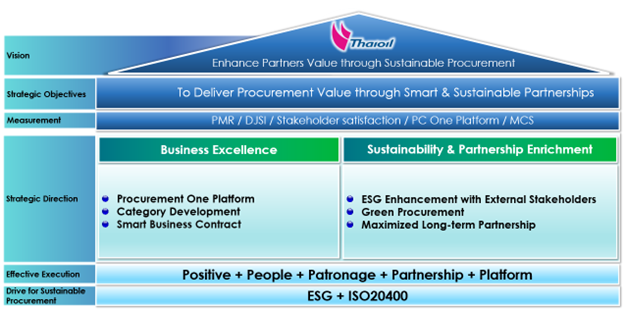

To achieve sustainable targets across the supply chain, Thaioil Group established 2022-2026 strategic direction towards sustainable procurement excellence as follows:

2022-2026 Strategic Direction towards Sustainable Procurement Excellence

Sustainable supply chain management strategy consists of two main pillars under the principles of “Accurate, Speed, Clear, and Fair.” For efficient and successful implementation of the strategy, Thaioil Group has adopted the 4Ps principles (People, Patronage, Platform, and Partnership) as the key drivers, consisting of:

-

1. People: To effectively implement the Sustainable Procurement Policy and Strategy, collaboration from all relevant functions is required. Therefore, the personnel of the procurement function, internal stakeholders, and suppliers will be developed to support the Company’s sustainability (ESG) targets.

2. Patronage: To deliver added values to meet the expectations of suppliers.

3. Platform: To implement reliable and global technology systems, such as SAP, SAP Ariba, and DocuSign, to improve business operations with suppliers. This aims to enhance accuracy, speed, clarity, and fairness for all suppliers towards the digital workplace.

4. Partnership: To build partnerships with business partners and formulate key performance indicators (KPIs) in accordance with the Company’s targets.

In addition, Thaioil Group strives to create the foundation of sustainable procurement under the ESG principle. The Company integrates the ISO 20400: Sustainable Procurement into the non-hydrocarbon procurement process. Also, the Company has established a five-year action plan to be a framework for further implementation. The details are summarized as follows:

- 1. Business Excellence: The Company establishes a robust platform and adopts technology to enhance the efficiency of modern working processes, such as:

The Company has reported the supplier practices and ESG programs to the executive management and the Board of Directors through the board-committee, namely Corporate Governance and Sustainability Committee (CG Board Committee), on an annual basis.

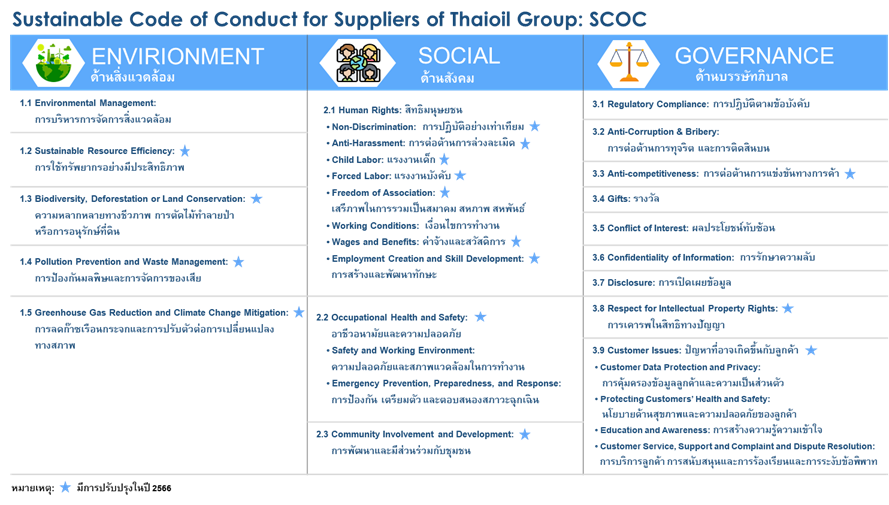

Sustainable Code of Conduct for Suppliers of Thaioil Group (SCOC)

To manage supplier’s practices in alignment with Thaioil Group’s vision, the Company strives to integrate sustainable practices throughout its supply chain. Since 2015, the Company has encouraged suppliers to adhere to the Sustainable Code of Conduct for Suppliers of Thaioil Group (SCOC), which covers three dimensions: Environmental, Social, and Governance. The purpose is to drive towards sustainable supply chain management, enhance strategic cooperation, and create long-term growth with suppliers. Therefore, new registered suppliers must acknowledge and comply with the SCOC.

In 2023, Thaioil Group reviewed and amended the SCOC to align with international standards and the changing global landscape. To ensure that all suppliers understand the SCOC, the Company has communicated the SCOC through Thaioil Group’s website and the supplier seminar 2023.

"Click Here" Sustainable Code of Conduct for Suppliers of Thaioil Group (2023 edition)

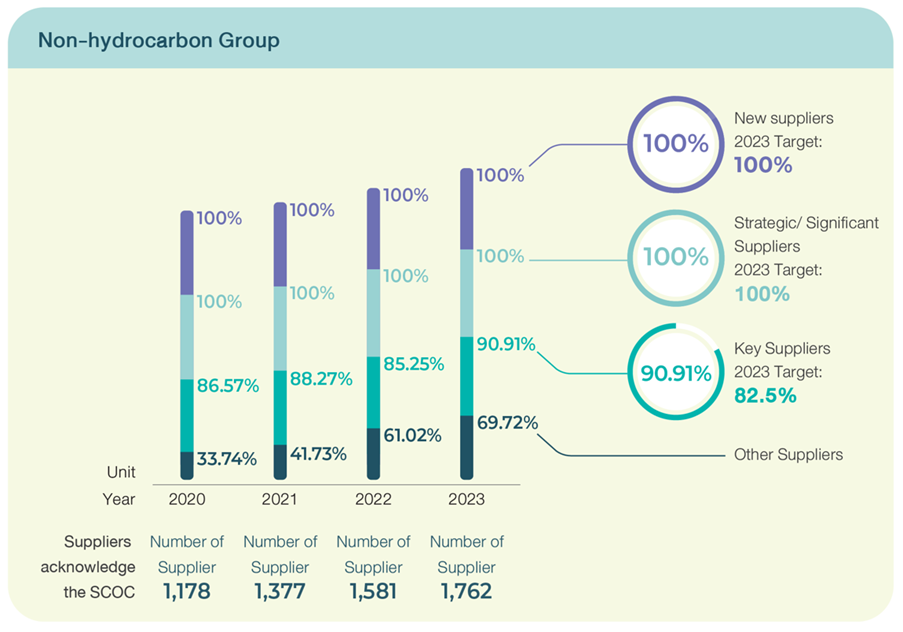

Performances 2023

Thaioil Group expects all suppliers to acknowledge the SCOC. To ensure the supplier’s understanding of the SCOC, the Company has communicated the SCOC through Thaioil Group’s website and annual seminars with all suppliers.

Thaioil Group’s Non-hydrocarbon Suppliers

For non-hydrocarbon suppliers, Thaioil Group has conducted the supplier selection process through the Ariba System, which embeds the supplier selection criteria in a preliminary supplier assessment form. The criteria include the preliminary assessment of the quality of products and services, and supplier’s financial status. In addition, it includes the assessment of sustainable procurement on Environmental, Social, and Governance (ESG) aspects, consisting of product delivery information, safety management, SCOC acknowledgement, third-party verification such as ISO9001, ISO14001, ISO/IEC17025, OHSAS18001, and ISO50001. In addition, there is a data verification process to examine policies and corruption prevention measures for the suppliers who potentially have corporate governance risks, such as the suppliers who are working with government agencies.

The post evaluation of suppliers after delivering products and services is conducted through the systems in which the methods will differ based on the priority of products and services. The sustainability topics are integrated into the evaluation criteria, such as the Security, Safety, Health, and Environment (SSHE) management and ESG management as well as the compliance with laws and regulations on the transportation of product and services, and the delivery of hazardous goods.

-

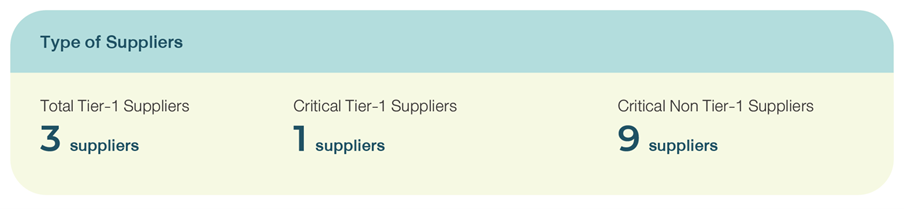

To align with the strategy, Thaioil Group classifies Tier-1 suppliers into three groups as follows:

- 1) Strategic/Significant Supplier: suppliers that are potential and significant to the Company to develop towards collaboration and mutual growth.

- 2) Key Supplier: suppliers that must maintain a long-term relationship to control costs or expenses that may increase in the future and require potential risk management.

- 3) Managed Supplier: suppliers are managed by relationships based on their performance.

Moreover, the Company classifies strategic/significant non-tier 1 supplier that provides products and services to the Tier-1 suppliers, whose products and services are considered of critical significance to our businesses.

.png)

Risk Management in Supply Chain

- • Risk Assessment

Thaioil Group implements a Supplier Lifecycle Management process that covers supplier registration, supplier qualification evaluation, supplier operation monitoring, supplier performance assessment, and supplier risk management. Supplier risks will be monitored through external databases, including Regulatory & Legal Risks, Financial Risks, Environmental, Social and Governance Risks, and Operational Risks. Moreover, Thaioil Group conducts supplier screening through supplier risk identification, considering both business relevance and negative impacts on ESG practices. These risks are in addition classified into country-specific risks, sector-specific risks, and commodity-specific risks. The result of supplier risk identification will be used to manage potential sustainability risks and select the suppliers for further supplier assessment process.

In addition, Thaioil Group has adopted a cost analysis tool in the supplier selection process. This tool will help to identify opportunities for the Company to reduce costs, manage risks, and enhance procurement efficiency. The result of the cost analysis will assist the Company in gaining valuable insight of the Company’s expenditures, allowing for improvements in operational efficiency, contract compliance, and cost management.

Thaioil Group conducts an annual risk assessment across the Company’s supply chain for all suppliers. The risk assessment has been conducted by different methods. For example, supply risks are assessed by Porter’s Five Force Model. Meanwhile, the sustainability risks have been assessed by category of products and services, covering ESG aspects and aligning with the seven core subjects of ISO 20400: Sustainable Procurement.

• Risk Management

Maintaining business continuity requires ensuring supplier management in compliance with contractual requirements, relevant regulations, and laws. Henceforth, Thaioil Group regularly conducts supplier and sustainability assessments of strategic suppliers and suppliers with high sustainability risks. The assessment includes desk and on-site practices to prevent business disruptions related to ESG issues. In addition, the Company has elevated the safety management for the suppliers in alignment with the international best practices. The suppliers’ safety performance is annually assessed by a third party. In the case of non-compliance, the Company will notify the suppliers to prepare the corrective action plan and set the target for them to implement the corrective action to achieve 100% compliance within a specified timeframe.

In terms of contract and delivery management, Thaioil Group has considered the impacts of the risks assessment and monitoring long lead items. The Company employs additional workers and extends the contract periods for urgent and significant works. To maintain the operational stability between the Company and suppliers, the Company uses compulsory KPIs to evaluate the performance after the product and service delivery. The compulsory KPIs not only include the aspect on quality and delivery time, but also sustainability aspects, such as reliability, safety, environment, occupational health, ESG management, and legal compliance with relevant regulations and laws. The performance indicates a specific-aspect scores and consolidates into an overall percentage. After completing the work, the Company will organize a meeting with supplier to identify further solutions and improvements. In addition, the supplier evaluation results are used as a criterion when rewarding suppliers for significant projects, such as the annual major turnaround project, to enhance supplier reputation

• Supplier Assessment

Thaioil Group is committed to conducting supplier assessment on sustainability topics and promoting suppliers’ capacity on ESG management. The Company has established a long-term plan to proactively evaluate the strategic suppliers. To identify the strategic suppliers, the Company has conducted a supplier risk analysis, including spending analysis, significance of products and services, supply risks, and sustainability risks. This helps manage risks within the supply chain and achieve 100% of strategic supplier assessment on ESG risks by 2026.

In 2023, Thaioil Group conducted a supplier assessment on ESG risks as follows.

- 1) Supplier Desk Assessment: The Company examined the certificates and assessment report issued by the Independent Accredited Auditing Body, including ISO14001, ISO50001, ISO45001, OHSAS18001, ISO9001, ISO17025, ISO27001, Green Industry Standard assessments by the Ministry of Industry, and certifications from the Thai Private Sector Collective Action Against Corruption (CAC), Corporate Social Responsibility, and the Department of Industrial Work Award (CSR-DIW Award) by the Ministry of Industry etc.

- 2) Supplier On-Site Assessments – Thaioil Group conducted on-site supplier assessments on sustainability topic, classified into two types as follows:

2.1) 2nd Party Supplier On-site Assessments: The onsite assessments are conducted by Thaioil Group’s internal functions. For example, Waste Management Audits are conducted by Thaioil Group's environmental team at the supplier’s site. Security, Safety, Occupational Health, and Environment (SSHE) practices are assessed by Thaioil Group’s safety team while the suppliers are working in Thaioil Group’s operational area. Meanwhile, compliance with contractual requirement and relevant regulations of the suppliers in Thaioil Group’s operational area will be assessed by end-user functions, operational functions, and safety functions. Moreover, during major turnaround (MTA), Thaioil Group’s executives will participate in on-site assessments with suppliers, Management Site Walk program, to ensure that significant suppliers comply with the SCOC.

2.2) 3rd Party Supplier On-site Assessments: The Company conducts onsite supplier assessment by Third Party Auditing Organizations that are accredited by the Standard-Setting Organization. In 2023, Thaioil Group collaborated with the Industrial Estate Authority of Thailand (IEAT), an accredited organization by the Ministry of Industry, to assess the Company’s sustainable management practices of suppliers who have high ESG risks and/or being the strategic/ significant suppliers. These on-site assessments are conducted based on the criteria developed from ISO20400: Sustainable Procurement to evaluate Environmental, Social, and Governance (ESG) aspects at the suppliers’ sites.

After supplier assessment, if any suppliers fail to pass or meet the assessment standards, Thaioil Group will work with the suppliers through online (remote) and onsite meetings to help them develop their corrective actions and improvement plan and provide them with the corrective action plan (CAP) template in order that each supplier can systematically solve the issues. The CAP will require suppliers to record the non-compliance issues, root causes, and proposed solutions while the expected deadline must be specified in the CAP, and submit the CAP to Thaioil Group within a specific period. Thaioil Group will then regularly organize meetings with suppliers to monitor the implementation progress and provide recommendations for further development and improvement. This collaborative approach not only mitigates potential ESG risks and promotes operational excellence, but it also fosters sustainable development in alignment with the Thaioil Group’s business practices. As a result, this builds trust and strengthens business relationships between Thaioil Group and suppliers.

In addition, Thaioil Group will compare the data of all suppliers' sustainability performances from the Supplier ESG Benchmark in each sustainability dimension. The Company will in addition share the performance data with the best sustainability practices in each sustainability dimension with other suppliers. This information provides valuables insights and can be applied in the supplier’s organization to support their improvement and enhance better sustainability performance.

Performances 2023

In 2023, Thaioil Group conducted a sustainable supplier assessment as follows:

.png)

Supplier and Employee Capacity Building

• Supplier Development and Capacity Building Program

Thaioil Group strives to develop and enhance the supplier capacity in sustainability management, covering ESG aspects, across its supply chain. The Company has regularly communicated knowledge, Supplier ESG programs, procurement procedures, and Thaioil Group commitment to all suppliers through various channels, such as annual supplier seminars, practical and theoretical trainings, and Thaioil Group’s website. Also, the Company has publicized ESG news through the Company’s Facebook pages and Supplier Relationship Management (SRM) Newsletters via Emails.

In 2023, Thaioil communicated information and conducted Supplier ESG Programs as follows:

|

Thaioil’s supplier seminar is conducted annually. In 2023, Thaioil Group organized a hybrid seminar to communicate its current vision, strategic direction, the 2024 procurement plan, sustainability management, the 3Es strategy (Enhance Clean Environment, Engage Society, Ensure Good Governance), and the Sustainable Code of Conduct for Suppliers of Thaioil Group (SCOC). Moreover, the Company also provided ESG knowledges in different areas, such as quality, security, safety, occupational health, environment, energy management (QSHE), biodiversity, human rights, corporate governance, and ESG best practices. The purpose was to enrich supplier’s understanding of sustainability management and apply the knowledge into their own businesses to support the Thaioil Group's sustainable development goals. |

.jpg) |

Thaioil Group SSHE Training Center is established to manage high-risk work. The purpose of the center is to enhance knowledge and skills and to share in-depth work experience between the Thaioil Group and its suppliers. This center also supports the safety and environmental management in the workplace to reduce the number of accidents from actual works. This is accomplished by conducting the joint trainings between the Thaioil Group and its suppliers, enabling them to acquire knowledge and understanding through this center before starting the actual work. |

|

Safe White Green Program is a Security, Safety, Occupational Health, and Environment (SSHE) management program. This aims to enhance the SSHE capabilities for the suppliers. Also, the Company continuously monitors the performance together with the suppliers. This program has been conducted since 2021. The program is an in-depth technical capacity development program that has a systematic development process through five steps: Coach, Up & Re-Skills, Control, Recognize and Share. |

|

|

The Green Industry certification training program for suppliers is conducted annually in collaboration with the PTT Group. This program encompasses both theoretical online sessions and practical workshop sessions for the suppliers throughout the year. This training program aims to motivate and guide suppliers in adopting environmentally friendly business operations. Throughout the training, Thaioil Group collaborated with recognized institutions, including the Management System Certification Institute (MASCI), which is a network institute of the Ministry of Industry and operates under the Foundation for Industrial Development. |

|

ISO 20400 Sustainable Procurement Training for Suppliers is conducted in collaboration between the Management System Certification Institute (MASCI) and Thaioil Group’s procurement function. This training aims to promote and support supplier’s knowledge and understanding regarding sustainable procurement approach, covering Environmental, Social, and Governance aspects. Moreover, the training encourages the suppliers to implement with their own suppliers to promote sustainable development throughout the supply chain. |

|

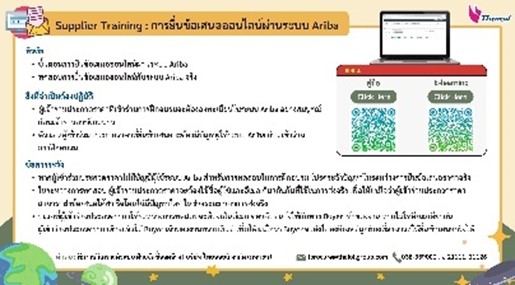

E-procurement Training Program includes SAP Ariba Network for supplier registration, Online Proposal Submission, Online PO, Contractor Management System (CMS), and Turnaround Work Progress Program for reporting progress during maintenance shutdowns. These programs can enhance work efficiency, reduce energy consumption, and contribute to environmental conservation by minimizing paper use in the work processes. In addition, the programs comprehensively cover various systems related to the entire procurement process. The trainings are designed for each system to serve the specific needs of the suppliers. |

|

A three-year collaborative academic cooperation agreement program with partners is designed to support social responsibility between Thaioil Group and its suppliers. Also, the program aims to enhance the knowledge and practical skills of the students who are participating in the project through practical works in Thaioil Group's refining and petrochemical units. This collaboration involves the expertise of Thaioil Group and its suppliers. |

|

PTT Group CG Day is a collaborative initiative with the PTT Group, organized on an annual basis. The initiative aims to promote and enhance supplier’s knowledge and understanding of Good Corporate Governance. In 2023, approximately 2,100 suppliers were invited to participate in this event through an online platform. |

|

Thaioil Group organizes relationship building activities for suppliers. This aims to ensure the supplier’s understanding and acknowledgement of the Thaioil Group transparency and commitment in the procurement process, such as No Gift Policy. There were 2,445 suppliers participating in the activities. |

|

Supplier ESG On-Site Assessment 2023 at the supplier’s operational site was conducted by an accredited institute with ISO standards, the Foundation for Industrial Development (FID), and the Management System Certification Institute (MASCI). This aims to provide recommendations from experts and Thaioil group for the suppliers which allow them to improve their sustainability (ESG) practices in their supply chain. |

2023 Performance

In 2023, Thaioil Group implemented initiatives to enhance the capabilities of suppliers as follows:

.png)

• Employee Development and Capacity Building Program

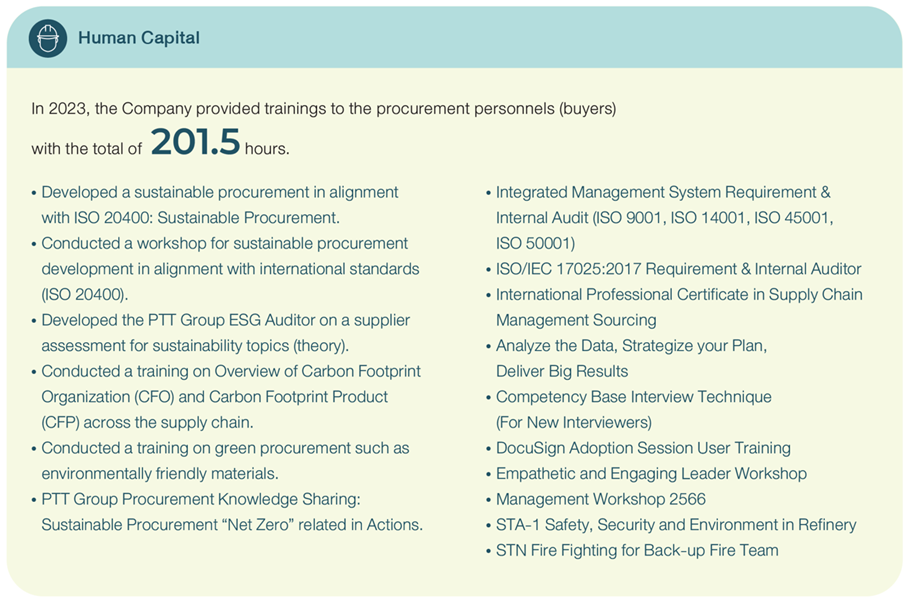

To ensure the effectiveness of sustainable procurement policies and strategies, Thaioil Group recognizes that it is essential to receive the cooperation from all stakeholders, including those who involved in the procurement, internal stakeholders, and suppliers. In addition, the stakeholders need to understand the principle and rationale of sustainable procurement. Therefore, the Company has actively enhanced the capacity on sustainable procurement for the personnels (including buyers) in procurement function, other relevant function, and internal stakeholders, through several trainings and activities. For example, the Company organized the trainings of sustainable procurement in alignment with ISO 20400: Sustainable Procurement, covering topics such as integrating Sustainability into Procurement Policy, strategies, and E2E Process, organizing the Procurement Function towards Sustainability, and developing robust Supplier ESG Program. This aims to enhance the understanding of the roles and responsibility in sustainable procurement among the personnels in the procurement function, other relevant functions, and internal stakeholders, who are the key driver of sustainable procurement. As a result, this will ensure that Thaioil Group will be able to achieve the sustainability (ESG) targets.

Supplier Engagement and Satisfaction

In 2023, Thaioil Group consistently improved the E-Procurement system, including the Contractor Management System (CMS), to ensure clarity, fairness, and professionalism in the Company’s procurement processes. This led to a higher supplier engagement and provided benefits for suppliers in terms of cost reduction and saving travel time, resulting in better supplier satisfaction. In addition, the Company adopted reliable technologies in the procurement process. For instance, the SAP Ariba system has been applied in supplier registration, bidding submission, and online procurement. Meanwhile, the Company has been applying DocuSign to facilitate the digital signature in the contract processes. Also, the Company organized trainings on the use of the SAP Ariba system for its suppliers.

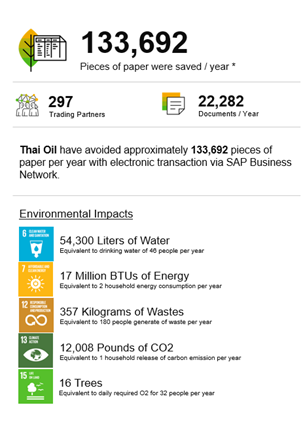

Furthermore, Thaioil Group has actively promoted the use of the Online Purchase Order (PO) system for suppliers via the E-Procurement system. This aims to simplify the working process and increase the convenience and speed of the procurement process for the suppliers. At the same time, the Company has reduced environmental impacts by saving 133,692 pieces of paper per year. Since adopting the Online PO system, the Company has reduced a total of 935,844 pieces of paper. This allows the Company to minimize resources and energy consumption.

In addition, Thaioil Group has conducted a survey for suppliers who participated in online bid submissions through the E-Procurement system. The findings revealed that most suppliers were highly satisfied with the system due to its cost-saving benefits. In comparison to traditional bid submissions, the system saved approximately 3,020 THB per submission and reduced travel time by 5 hours 40 minutes

Thaioil Group has developed the Contractor Management System (CMS) to support the post-award processes for suppliers. Suppliers can submit a request to make a contractor card for entering Thaioil Group’s facilities through the CMS System anywhere and anytime. The system assists in recording and verifying contractor information in accordance with the Personal Data Protection Act. Moreover, suppliers’ performance can be evaluated via the Contractor-Performance Management System (C-PMS). After completing tasks in the contracts, Thaioil Group will take the KPIs of various aspects, such as ESG, SSHE, or quality of work as agreed with suppliers, to evaluate supplier performance and open a discussion floor for further improvements.

Performances 2023

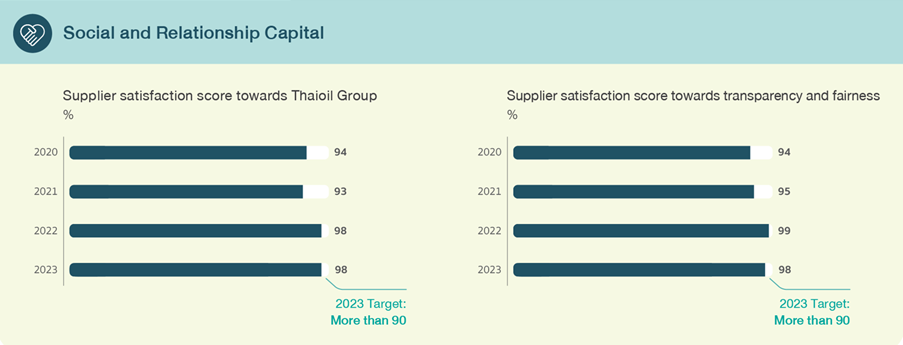

To ensure that Thaioil Group recognizes the needs of suppliers, the Company conducts engagements, communications, and discussions through a supplier engagement to understand and gather suppliers’ perspectives towards Thaioil Group in terms of procurement management principles, services, transparency, and fairness. Thaioil Group will then consolidate all of the collected suppliers’ opinions into the Company’s decision-making and operational processes. In 2023, Thaioil Group conducted a supplier engagement survey through a third party expert, and the survey results as follows:

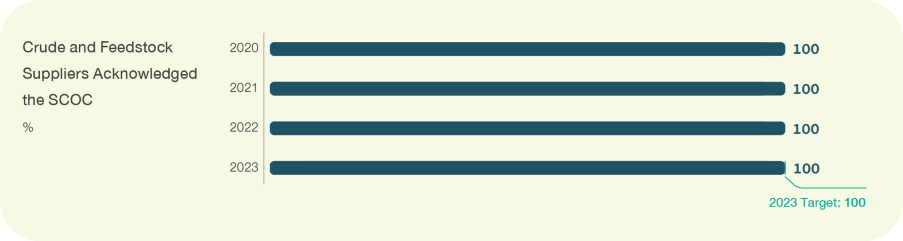

2. Crude and Feedstock Suppliers Management

Thaioil Group places significant importance on crude and feedstock supplier management in the refining process. The Company has efficiently collaborated with the suppliers to ensure that all Thaioil Group's products across the supply chain have been supervised and that there are no sustainability risks from crude and feedstock procurement. In addition, the Company has implemented the SCOC as a guideline to govern and communicate with the strategic crude and feedstock suppliers. In 2023, 100% of strategic crude and feedstock suppliers acknowledged and complied with the SCOC. There were no ESG risks that affected the business operation.

Sustainability Indicator

• Crude and Feedstock Supplier Information

• Expenditure 2023

.png)

• Governance

Thaioil Group expects all suppliers to acknowledge the Sustainable Code of Conduct for Suppliers of Thaioil Group (SCOC). To ensure understanding of the SCOC by suppliers, the Company communicates the SCOC through Thaioil Group’s website and annual supplier seminars.

Update : February 2024

.JPG)